Setting Flexible Goals

In the past, I had made several attempts to hike/walk 10,000 steps a day - every day - for an entire year. By the 3rd week in January, I would typically miss a day due to various reasons or excuses. Once a day was missed, the long term goal was missed, and further motivation to exercise was lost.

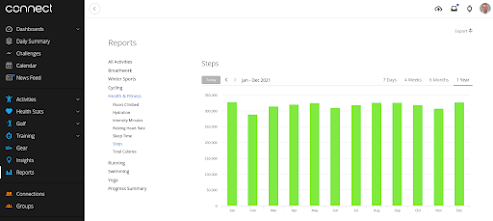

In 2021, I made two modifications to the plan. The goal was changed to 70,000 steps per week, and every day I read the following words which were summarized from the book “Atomic Habits” by James Clear:

- It takes 1 month to make or break a habit

- Plan for failure: If you miss a day, get back on track immediately

- Whenever there is a gap between your habits and goals, habits will always win: Identify and fix the gaps

Changing to a weekly vs. daily goal allowed for some flexibility. If I missed the average daily number of steps, I resolved to make up the shortfall in the remaining days that week. And I could build up a surplus of steps early on to help with an off day later that week. Since making these changes just over a year ago, I have met my goal of hiking/walking 70,000 or more steps per week for 53 consecutive weeks!

There was more than one Sunday when I had to walk ~9 miles in a cold rain to meet my weekly goal. And with this flexible goal I was able to spend more time with my 98 year old father when he fell ill and eventually passed in July, while still reaching my goal. As important as your goal may seem when you set it, more critical and unexpected issues are likely to arise, and you should build in the flexibility to deal with these circumstances when they happen without giving up on your goal.

This year, I’ll be switching my weekly goal to reach 500 “intensity minutes” (as measured by my Garmin fitness watch) rather than steps so that in addition to continued hiking and walking, activities like cycling, kayaking, disc golf, and yard work can be added to my activities. And I plan to apply the same flexible system to other goals such as eating healthier and work related training & certifications.

In summary: Making small changes to goals that allow for flexibility can make the difference between achieving or failing at that goal.